diy injection molding press

Ernie Di Siro is the Molding Manager for Nordson EFD LLC a proprietary injection molder. Based on the part that was molded estimate or measure the amount of plastic resin needed to.

Plastic Injection Moulding Machine Model 4 Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

A 36-year-old male machine operator died when he was crushed between the platens of a 3200-.

. Given the enduring interest in this piece of equipment we thought it. Two ⅛ guide pins are pressed into one half of the mold and the other holes are reamed out just slightly to 0126. Two little blocks of 6061 aluminum make up the halves of the mold.

Instructions for building one also are on the Action Box channel. The economic upturn is bringing the injection molding manufacturing market along for the ride. But wall thickness also depends on the material used.

Once you have your frames in place proceed with setting up the frames for. Be part of the community. Thus we refer to it as an injection molding attachment for a drill press.

You will receive a notice of your reservation slot and expected delivery date. Thus we refer to it as an injection molding attachment for a drill press. These rewards will be shipped as fast as we can assemble the machines.

Step 3 Pour in. VersaCourts state-of-the-art electric injection molding presses will help reduce overall power consumption during the manufacturing process by up to 70 - compared with previous hydraulic powered presses. 3200 ton horizontal injection mold press.

Reduced waste heat from manufacturing. DIY Injection Molding Step by Step 1. Ad Options From 10 Ton Manual-Powered Models To Heavy-Duty 100 Ton Electric-Powered Presses.

Design the Mold in CAD First pick the CAD software tool of your preference to design the mold insert. The injection molding is a process to form the plastic resin into the desired shape. The unit itself measures approximately 12 inches long x 1-34 inch diameter at its widest point and weighs just 3 pounds.

You wont need a machine shop at home and you can even build the mold itself using a DIY CNC machine. That article continues to capture eyeballs getting as manyand sometimes morepage views than current content. Although many people now think of hobbyist 3D printers when they want to make small quantities of plastic parts at home 3D printing isnt the only way to go.

A brand new machine like the Galomb is circa 1500-1800. These machines are designed to make it easy to prototype injection molded parts test molds and even do small production runs. DIY Injection Molder Buster Beagle 3D.

After building our DIY homemade CNC milling machine from scratch we wanted to push our home shop to the limits. So we are offering to ship machines stating in November without any pledge limits. Place the side with the sprue and air holes face up.

A 1500 benchtop injection molding machine has been funded via Kickstarters crowdsourcing funding process. Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould or mold. Is creating DIY and Crafts Videos Animations and More.

Step 2 Setup the modelitem in the mold. In operation plastic is melted in the injection barrel of the machine by two 14 inch diameter x 2-12 inch long cartridge heaters. If a machine requires more than 1 operator and if each operator is.

Excellent Range of Products at attractive prices. Connect via private message. Read on to see the best DIY and desktop injection molding machines.

Homemade injection molding machine filling various molds including a see through one were you can see the hdpeplastic filling the mold. Become a patron to. This series will discuss what you should consider before writing a check beginning with the clamping unit.

Ad Free Shipping Available. Injection molding machine press the melted plastic into the mold and cool down by cooling system into solid designed shape almost all thermoplastics using this method comparing with other processing way injection molding has advantage of accuracy productivity it has higher. DIY Injection Molding How to Get Started Step 1 Get frames to make the mold.

This means shorter cycle times resulting in more parts produced per hour and lower production cost. 3D Print the Mold To 3D print the mold its essential to pick a material that can withstand the temperature and. Be sure you will get the best out of more than 4000 used machines and tools.

Ad At Surplex you will find used machinery and industry equipment at best prices. The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity. As electric presses consume far less energy they also generate less waste heat during operation.

The unit itself measures approximately 12 inches long x 1-34 inch diameter at its widest point and weighs just 3 pounds. Material for the part is fed into a heated barrel mixed and injected. LNS Technologies Model 150A.

By November of 2013 our production of the bench model injection machines should no longer be in start-up mode. He has 40 years of injection molding experience starting out as a machine operator. About seven years ago PlasticsToday published an article about a tabletop injection molding machine the 20A PIM-Shooter developed by LNS Technologies Scotts Valley CA.

Injection moulding can be performed with a host of materials mainly including metals glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. Jim Fattori is a third-generation injection molder with more than 40 years of molding experience. The first step in our injection molding setup is to create a mold.

On average injection molded parts should have a wall thickness that ranges from 008 2mm to 016 4mm but thin wall injection molding can go as thin as 002 05mm. First two 0124 holes are drilled through both blocks to hold guide pins that will ensure the mold halves are properly aligned. Maffei 3200 Ton horizontal injection molding machine.

The custom parts are required to complete the DIY Injector molding machine by Buster Beagle 3D and all the parts were custom designed and manufactured to withstand the heat and pressure of the. With the market percolating more molders are looking at new presses. In operation plastic is melted in the injection barrel of the machine by two 14 inch diameter x 2-12 inch long cartridge heaters.

Unlock 343 exclusive posts. The Crafsman - Steady Craftin. It sure looks a lot more robust than the typical benchtop injection molding machines I had been seeing.

We designed and developed a homebuilt full. The hand-operated machine which reminds me of an innovative professional-looking Gadget Freak. He is the founder of Injection Mold Consulting LLC.

As luck would have it you can get a nice-looking pneumatic press for less than 350 and with a little more money spent Kurt found he could convert it into a functional injection molding. Small Injection Molding Machine from Galomb. How to Specify an Injection Molding Machine.

Bestseller Books Online Build A Plastic Injection Molding Attachment For A Drill Press Vincent R Plastic Injection Molding Plastic Moulding Plastic Injection

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

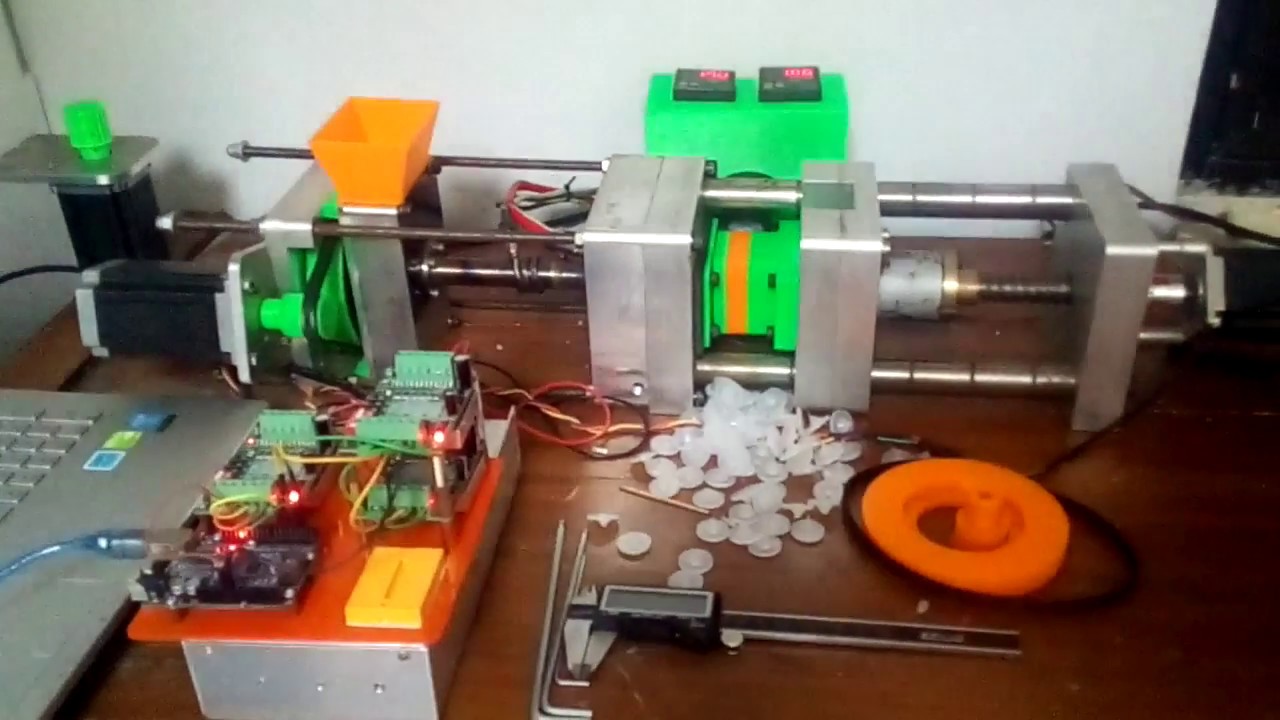

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Home Injection Molding Diy Molding Injection Moulding Plastic Injection Molding

Up For Sale Is A New Unused Powerlab Model 330 1 X2f 3 Ounce Benchtop Injection Plastic Moulding Plastic Injection Molding Plastic Injection Moulding Machine

Micro Injection Molding Machine Injection Machine Plastic Injection Molding Plastic Injection

Pin By Ahmad On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Plastic Moulding

Make Your Own Injection Molding Machine Make Diy Molding Diy Projects Homemade Machine

Homemade Plastic Injection Molding Machine Plastic Injection Plastic Injection Moulding Machine Plastic Injection Molding

Build Make Plastic Injection Molding Drill Press Attachment Diy How To Plastic Injection Molding Plastic Injection Plastic Moulding

1 300 Hobby Business Plastic Injection Molding Machine Molder Press Free Mold Ebay Refurbi Plastic Injection Moulding Machine Plastic Moulding Diy Molding

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Injection Moulding Mould Design

Desktop Injection Molding Machine Injection Machine Plastic Injection Molding Plastic Moulding

Diy Injection Molding Machine Plastic Injection Moulding Machine Plastic Injection Molding Plastic Moulding

Injection Molding Machine By Scorch Homemade Plastic Injection Molding Machin Plastic Injection Moulding Machine Plastic Injection Molding Plastic Injection

Electronics Cars Fashion Collectibles Coupons And More Diy Molding Plastic Injection Molding Plastic Moulding

Plastic Injection Molding Lns Technologies Plastic Injection Molding Machines A Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Diy Injection Molding Plastic Injection Molding Plastic Injection Injections

Make Your Own Injection Molding Machine Make Plastic Injection Molding Diy Molding Epoxy Resin Crafts